Guides, tips, and case studies on 3D printing

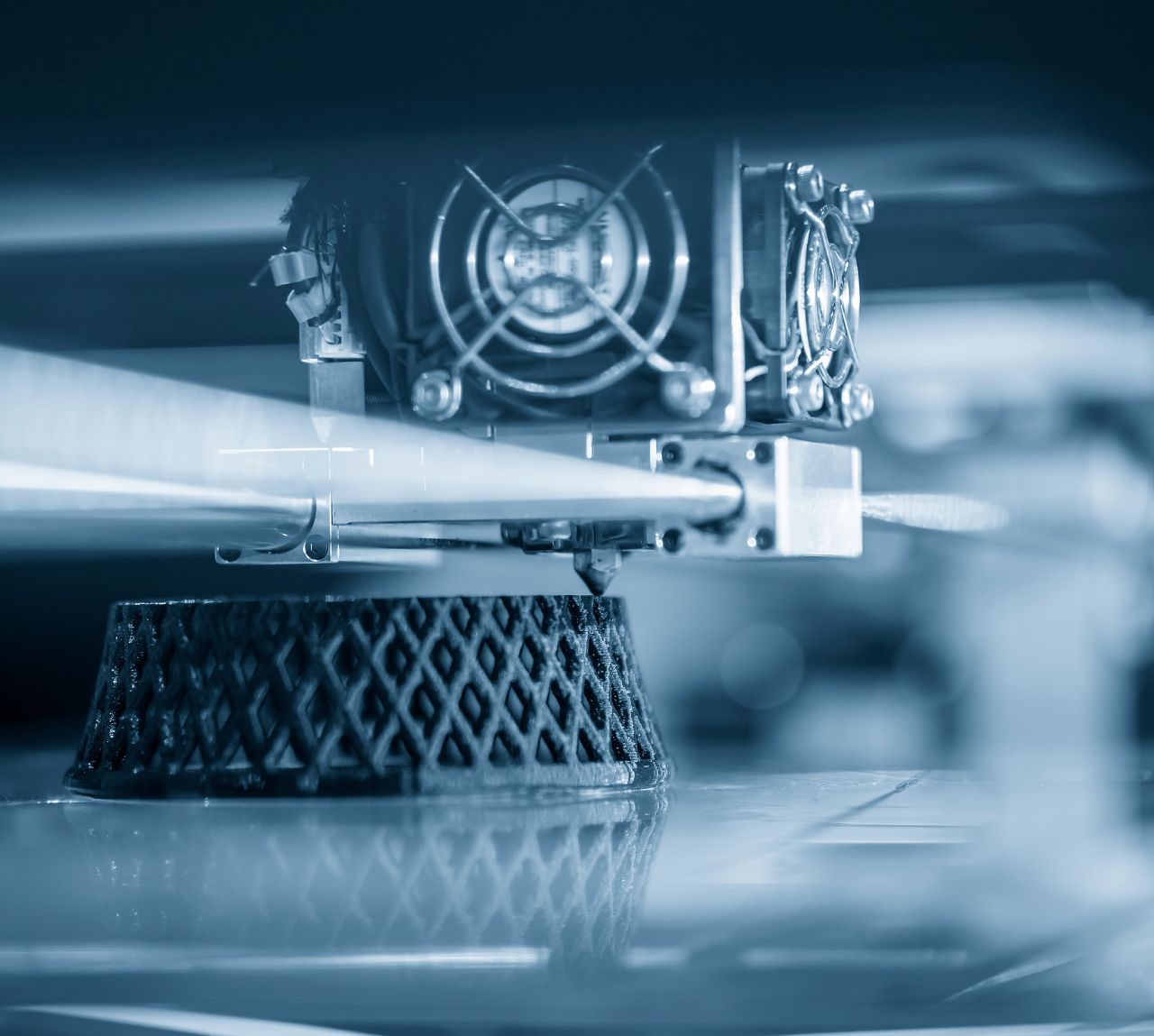

Introducing Fast Forward: Redefining the Future of 3D Printing Speed

Experience a quantum leap in 3D printing efficiency with Fast Forward, our groundbreaking line of high-speed printing materials. Engineered to accelerate the additive manufacturing process, Fast Forward unleashes unrivaled speed without compromising on precision or...

Elevate Your 3D Printing Game with ABS FAST Forward

Get ready for a game-changing leap in 3D printing with ABS FAST Forward. This advanced ABS filament is tailored for high-speed printing, revolutionizing the entire additive manufacturing process. Its innovative formulation ensures swift and precise extrusion, enabling...

Elevate Your 3D Printing Game with ‘Doctor Filament’: Your Definitive Guide to Printing Excellence

Introducing 'Doctor Filament' – Your go-to resource for unraveling the world of 3D printing filaments! Dive deep into a treasure trove of knowledge about various filaments, their applications, and insider tips from industry experts. Whether you're a seasoned maker or...